Your shopping cart is empty!

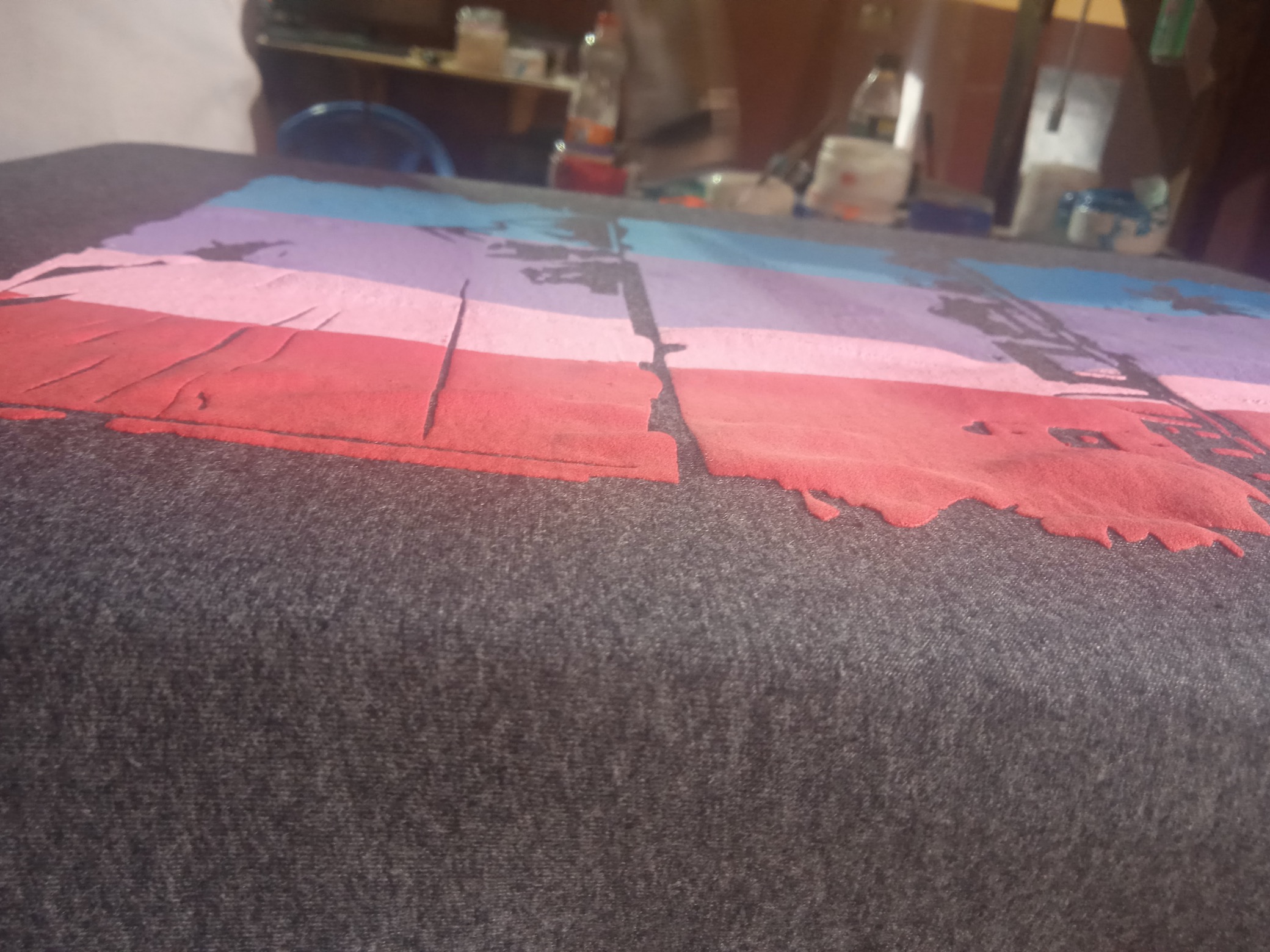

Printing with Puff Plastisol

Additive

Adding Antex Puff additive to your screen printing process

can be an innovative way to bring more life and beauty to your print.

When heat is added to puff ink, a screen printing ink additive,

it slightly rises off the garment like a newly baked loaf of bread puff effect. Puff additive gives your print a three-dimensional element.

Puff ink additives can be used on a whole artwork you are printing or you can use it to highly certain specific areas of your screen printed design.

Antex Puff plastisol ink additive can be used as a transparent

past or can be mixed with any colour of the Antex NF series of plastisol inks. When mixed together in the right ratio the outcome obtained is a suede puff effect.

How best to mix Antex Puff plastisol additive with

your printing paste.

How much additive is added determines how much the ink

will rise.

When using puff ink, it's crucial to weigh the appropriate

amounts of additive and paint.

If you add too little you will not see the effect after curing. If

you add too much the artwork might break after printing.

Antex puff additives come highly concentrated, so mixing

should be done in the right proportion to get the best effect.

The best ratio of mixing Puff plastisol additive you printing

paste is

5%(additive) mixed with 15%(plastisol paste) and mix well.

Once you've placed the ink on your clothing in the desired

design, it will rise with the heat as it passes through a dryer or

heat gun. During the process of drying all the moisture within

the ink will evaporate to leave behind a solid bold colour.

Your screen's mesh count determines how open the holes

are, and the lower the mesh count, the

more open the holes are, which leads to more ink deposits

and a puffier print. Puff does not work

well with fine mesh, this is because the foaming particles in

the additive when activated tend to

rise thereby sealing finer details in your print.

Puff screen printing advantages:

Rapid printing methods for high-volume printing

Can be used to print with a variety of additional inks and effects.

Capable of creating multicolour designs

High-strength, won't fall apart or peel off

Typically less expensive and with a professional finish

Can print on the majority of fabric types

Leave a Comment